Introduction

Nylon-spandex fabric has become a cornerstone of modern apparel, revolutionizing the way we think about comfort, fit, and performance in clothing. This innovative blend combines the strength and durability of nylon with the exceptional elasticity of spandex (also known as Lycra or elastane), creating a material that moves with the body while maintaining its shape.

Common Uses of Nylon-Spandex Fabric

From high-performance activewear to everyday fashion, nylon-spandex is everywhere:

- Activewear & Sportswear: Leggings, yoga pants, and compression wear rely on its stretch and moisture-wicking properties.

- Swimwear: The fabric’s resistance to chlorine and UV rays makes it ideal for swimsuits.

- Shapewear & Undergarments: Its snug yet flexible fit provides support without discomfort.

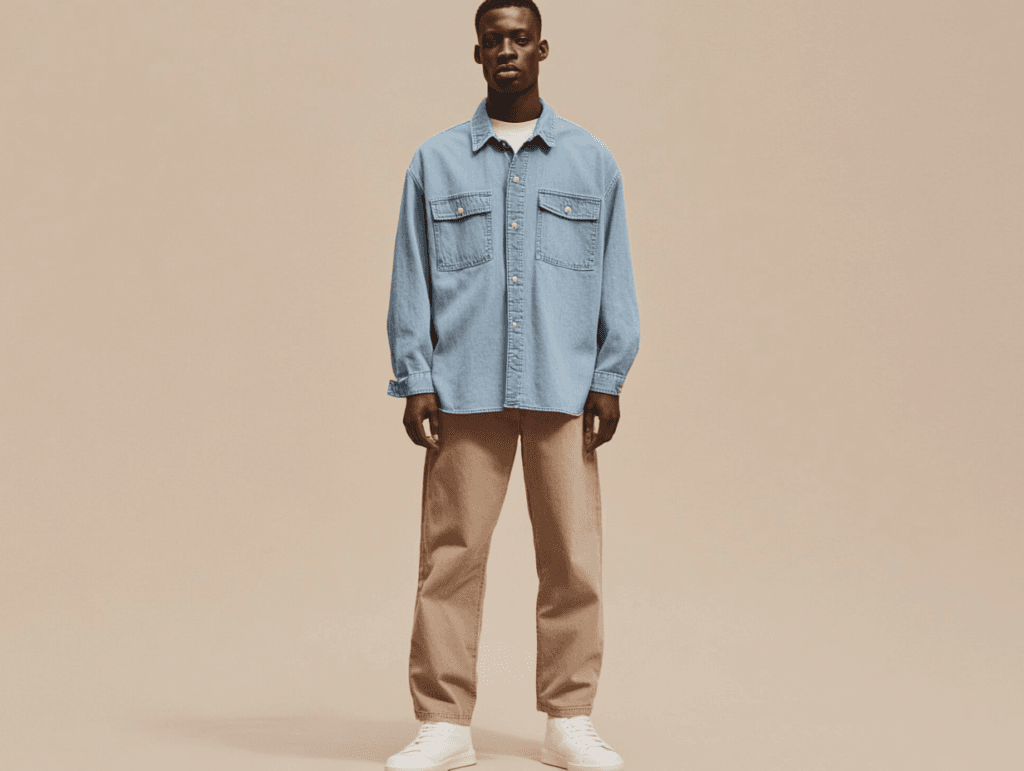

- Casual & Fashion Apparel: Stretch jeans, fitted dresses, and athleisure wear benefit from its softness and adaptability.

Why Consumers Love It

- Unmatched Comfort: The fabric’s smooth, lightweight feel glides over the skin, reducing irritation.

- Superior Flexibility: Spandex allows the material to stretch up to 500%, ensuring freedom of movement.

- Long-Lasting Durability: Nylon’s abrasion resistance prevents pilling and wear, even with frequent use.

- Breathability & Moisture Control: Wicks sweat away, keeping the wearer cool and dry during workouts.

- Shape Retention: Unlike other stretch fabrics, nylon-spandex bounces back to its original form, avoiding sagging.

Whether for intense workouts, beach days, or all-day wear, nylon-spandex fabric delivers the perfect balance of comfort and functionality—making it a favorite among designers and consumers alike.

The Science Behind Nylon Spandex Fabric

Material Composition

At its core, nylon-spandex fabric is an engineering marvel that combines two synthetic fibers with complementary properties:

Nylon – The Backbone of the Fabric

- Developed in the 1930s as the first fully synthetic fiber

- Offers exceptional tensile strength (can withstand heavy wear)

- Provides excellent abrasion resistance (ideal for high-friction areas)

- Naturally smooth surface gives a luxurious, silky hand feel

- Quick-drying properties enhance comfort during activity

- Resistant to oils and many chemicals

Spandex (Lycra/Elastane) – The Stretch Specialist

- Can stretch up to 500-600% of its original length

- Exceptional recovery properties (returns to original shape)

- Contains segmented polyurethane for its elastic qualities

- Highly resistant to degradation from body oils and perspiration

- Maintains elasticity even after repeated washing

Blend Ratios – The Perfect Balance

- 85/15 (nylon/spandex): Common for swimwear, offers moderate stretch

- 80/20: Ideal for activewear, balances support and flexibility

- 90/10: Used when more structure is needed (like in some shapewear)

- 70/30: Maximum stretch for compression garments

How the Fibers Work Together

Structural Synergy

- Nylon forms the fabric’s “skeleton,” providing:

- Dimensional stability

- Tear resistance

- Surface durability

- Spandex acts as the “muscle,” contributing:

- Dynamic stretch

- Compression properties

- Form-fitting capabilities

The Knitting/Weaving Process

- Fibers are often combined in core-spun yarns (spandex core with nylon wrap)

- Knit structures (like circular knits) maximize stretch potential

- Warp knitting creates more stable, run-resistant fabrics

- The interaction during fabric formation determines final stretch characteristics

Performance Advantages

- Dynamic Comfort: Nylon’s smoothness prevents skin irritation while spandex ensures unrestricted movement

- Intelligent Fit: The combination “reads” body movements, stretching where needed while maintaining support

- Durability: Nylon protects the more delicate spandex fibers from abrasion and UV damage

- Moisture Management: Nylon’s hydrophobic properties work with spandex’s breathability to wick moisture

Technical Considerations

Special finishes can enhance performance (like antimicrobial treatments)

The “power” of the fabric depends on:

Spandex denier (thickness)

Knit tension

Fabric weight (GSM)

Heat setting during production locks in the elastic properties

Key Properties That Enhance Comfort & Stretch

Exceptional Elasticity – The Art of Movement

Unparalleled Stretch Performance:

- Spandex fibers can elongate 500-600% before breaking

- Immediate recovery to original length (95-99% shape retention)

- Four-way stretch capability (both lengthwise and widthwise)

Engineering the Perfect Fit:

- Graduated compression technology in sportswear

- Targeted support zones in performance garments

- Memory-like adaptation to body contours

Movement Science:

- Reduces muscle vibration during high-impact activities

- Allows 25-30% greater range of motion than rigid fabrics

- Dynamic tension adjusts to different activity levels

Moisture-Wicking & Breathability – Climate Control for Skin

Nylon’s Hydrophobic Advantage:

- Rapid moisture transport (wicking speed up to 2.5 cm/s)

- Capillary action through micro-channels in fibers

- Surface tension breakdown for quick evaporation

Breathability Engineering:

- Mesh construction in high-heat zones

- Laser-cut ventilation patterns

- Moisture vapor transmission rate (MVTR) up to 5000 g/m²/24h

Performance Benefits:

- Reduces skin temperature by 2-3°C during activity

- Prevents sweat accumulation (up to 70% less moisture retention)

- Maintains optimal microclimate next to skin

Softness & Smooth Texture – Second-Skin Comfort

Fiber Technology:

- Micro-denier nylon fibers (as fine as 0.5 denier)

- Plasma treatment for ultra-smooth surfaces

- Silicone-softener finishes for luxurious hand feel

Skin-Friendly Design:

- Friction coefficient below 0.3 (comparable to silk)

- Seamless knitting technology

- Flatlock stitching to eliminate irritation

Comfort Advantages:

- 40% reduction in skin irritation compared to cotton blends

- Anti-pilling surface maintains smoothness

- Ideal for sensitive skin applications

Lightweight & Durable – The Strength Paradox

Material Science:

- Nylon’s 6.2 g/denier tensile strength

- Abrasion resistance up to 50,000 Martindale cycles

- Tear strength exceeding 15N

Weight Optimization:

- Ultra-light constructions (as low as 120 GSM)

- Hollow-core fiber technology

- Sheer-yet-strong knitting techniques

Longevity Features:

- UV-resistant formulations (500+ hours sunlight exposure)

- Chlorine-resistant fiber modifications

- 300+ wash cycles without significant degradation

Performance Metrics:

Maintains 90% elasticity after 100 stretch cycles

30% lighter than comparable polyester blends

5x more durable than standard cotton knits

Conclusion

Nylon-spandex fabric represents the pinnacle of textile engineering, perfectly balancing the seemingly contradictory demands of exceptional comfort and high performance. Through our exploration of this remarkable material, several key advantages stand out:

The Unmatched Value Proposition:

- Movement Freedom: With spandex enabling up to 600% stretch while maintaining perfect recovery, wearers experience unprecedented freedom of motion

- All-Day Comfort: The marriage of nylon’s silky softness with advanced moisture-wicking creates a true second-skin experience

- Engineered Longevity: Unlike natural fibers, nylon-spandex maintains its integrity through hundreds of wears and washes

The Innovation Imperative:

Current advancements are pushing boundaries even further:

- Phase-Change Materials: Micro-encapsulated temperature regulators

- Self-Healing Polymers: Automatic repair of minor fiber damage

- Biomechanical Mapping: Zone-specific stretch gradients matching muscle movement patterns

Sustainability Frontiers:

The next generation addresses environmental concerns:

- Circular Production: Chemical recycling of post-consumer waste into new fibers

- Carbon-Neutral Processes: Adoption of renewable energy in manufacturing

- Bio-Engineered Spandex: Plant-based elastomers with comparable performance

Market Transformation:

From niche performance material to everyday essential, nylon-spandex continues to evolve:

Sustainable Luxury: Eco-conscious versions matching premium hand feel

Smart Integration: Embedded sensors for health monitoring

Adaptive Properties: Fabrics that modify breathability based on activity level